Anterovium - stock.adobe.com

IoT battery outlook: Types of batteries for IoT devices

An IoT deployment won't get off the ground without the proper power supply. Learn about the different types of IoT batteries, as well as some newer battery technologies and alternatives.

One of the most critical components of any IoT deployment is how the devices are powered. Hard-wiring is an option, but for optimal mobility and coverage, most IoT devices must be wireless, putting the onus of IoT power on batteries.

What types of batteries should you use? Sure, a smart lock can run for two years on two AA batteries in a smart home -- maintaining these locks every couple of years doesn't take much effort. But scale this to hundreds, if not thousands or millions, of such locks whose batteries need replacing every two years, and things can get out of control quite quickly.

The sheer volume of batteries isn't where IoT's power problems end. IoT battery issues are compounded not only by connected sensors in remote, difficult-to-reach or dangerous locations, but also by their surroundings: Temperature, humidity and other environmental conditions can be detrimental to battery life. Likewise, user behavior -- for example, how a device is treated during shipping or storage or whether a device is used properly by an end user -- can also affect battery life.

Regardless, batteries are still considered one of the best options to power IoT devices. Let's take a look at some of the most common IoT batteries, as well as technologies on the horizon that can help or even replace batteries in the future.

Understanding IoT power requirements

The exact amount of power required for an IoT deployment varies depending on the hardware, software and use case. For example, an IoT sensor installed in a vineyard that measures temperature, humidity and moisture levels may only send a small amount of data a few times an hour or day to a gateway over a mesh network. On the other hand, an IoT-enabled medical pump may need to connect wirelessly to a hospital's Wi-Fi and maintain a near-constant connection to send health data on a regular basis -- by the minute or more often.

It's also important to note that, while that agricultural sensor may only send a small burst of data a few times a day, it will consume little energy while in sleep mode and require a burst of energy when transmitting data; this can be detrimental to certain types of batteries. Other IoT devices that require constant power put strain on the battery but do not have such energy spikes.

You must also take environmental conditions into account. In industrial processes, batteries may be subjected to harsh environments. Battery options are available with specialized casings and seals to prevent dust, moisture and chemicals from getting into the battery. Other batteries must operate in extreme temperatures. For example, the Panasonic BR-A series of lithium coin batteries can withstand temperatures from -40 to 125 degrees Celsius.

The hardware of an IoT device, including the transmitter, sensors and computing card, affect power consumption. For example, an Adafruit GPS chip uses 25 milliamps during tracking and 20 mA during navigation, while an Intel Edison computer card uses 100 mA when the radio is turned off. Then, an Aruba Bluetooth Low Energy (BLE) beacon, equipped with two coin cell batteries, offers 2,000 milliamp-hours (mAh) of energy.

In addition to hardware, the software and communications protocols used in an IoT system affect power consumption. Many IoT applications and protocols are designed for lower power consumption and low-power data transmission, such as the Z-Wave and Zigbee home automation communications protocols. A Z-Wave device -- for example, a door or window sensor, motion tracker or smoke detector -- doesn't connect directly to the internet. Instead, it connects to a smart home hub that either analyzes data locally or sends it to the cloud for analysis. A sample Z-Wave transmitter uses 23 mA. A Zigbee device, which uses multinode mesh networking to relay data to a hub or gateway, may use anywhere from 5 mA to 34 mA.

Choosing IoT batteries: 3 topics to consider

Here, Shawn Chandler, IEEE senior member and director of IT at PacifiCorp, offers three top considerations to keep in mind when selecting batteries for your IoT devices.

- Electrical discharge performance

Your primary consideration should be the performance of the battery, which includes service voltage, or the voltage of the electronics; peak current, the maximum amount of current the battery needs to deliver; and performance over time. Many IoT devices are designed for low-voltage, low-energy consumption and thus have a long lifetime using a relatively small-energy storage battery. Some devices, such as those configured for transmitting larger batch data sets across mobile networks, may require a higher peak-current or operating voltage due to the radio technology or be tasked with longer-range transmissions or even more frequent transmissions. It's important to model the battery and the device performance in specific terms, as the cost to replace a battery can be prohibitive. Terms to watch for include peak-load current (amps) and operating voltage requirements (volts).

- Self-discharge and charging

Batteries have different self-discharge rates over time as a matter of internal battery chemistry and physics. It's important to understand the self-discharge characteristics and include these when planning for device performance. Charging characteristics are yet another consideration. Most batteries are not rated to perform at less than 20% charge capacity of the battery; at this point, they require replacement or charging. The key feature is the cycle life, referring to how many cycles from 100% to 20% a battery may experience before needing replacement. Charge time may be another feature to think through. Most importantly, consider that many battery chemistries lose the ability to take a full charge over time, meaning their total capacity is reduced slowly over time. Terms to watch for include self-discharge per month (% of total charge), charge time (in minutes or hours) and cycle life (total number of cycles of 80% discharge before the battery needs replacing). Just as important is a system to track the state of all the IoT device batteries in use in order to proactively maintain devices needing replacement and effectively plan for such costs.

- Physical battery features and safety

Batteries have been widely used since the late 19th century, but there have been many changes to battery chemistry and safety features over time. When choosing IoT batteries, consider their fit to the operating environment and device, including potential for shock, physical damage and overheating weighed against the battery type and chemistry. Also, consider weather factors, such as exposure to humidity, moisture, and high and low temperatures, as well as toxicity considerations for the battery itself, such as disposal planning, hazard planning and compliance with local and regional regulations, if any. For example, protection circuits are required for lithium-ion batteries within the device to prevent specific fire and chemical safety hazards. Terms to check for are recommended charge and discharge temperature, or operating ranges, safety requirements (circuit protection, material data safety sheet notes for toxicity, handling and operating procedures) and maintenance requirements.

Types of batteries

Chemical batteries -- lithium, alkaline or lead acid -- convert chemical energy into electric energy. A chemical reaction causes electrical ions to flow from the negative terminal (anode) to the positive terminal (cathode) of the battery through an electrolyte. To recharge the battery, that flow is reversed and thus converts electricity back into chemical form.

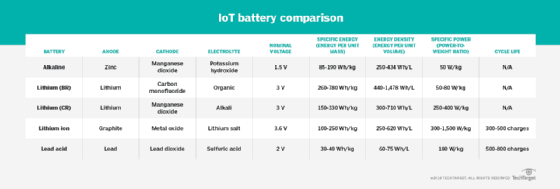

Batteries are often compared based on metrics, including but not limited to:

- voltage;

- energy per unit mass, also called specific energy, measured in watt-hour per kilogram (Wh/kg);

- energy per unit volume, also called energy density, measured in watt-hour per liter (Wh/L); and

- power-to-weight ratio, also called specific power, measured in watts per kilogram (W/kg).

Lithium is the lightest metal and has the greatest power-to-weight ratio of any chemical battery, making it suitable for small items, such as wearables, beacons and sensors. Lithium batteries come in button cell (BR) and coin cell (CR) varieties.

Whereas many lithium batteries are not rechargeable, most lithium-ion batteries are, though it comes with the tradeoff of increased cost. Lithium batteries retain shelf life well, making them a popular option. Other lithium batteries include lithium-ion polymer, lithium cobalt, lithium manganese, lithium phosphate and lithium titanate.

Alkaline batteries are an older technology. Available as AAA, AA, C, D, N and 9 volt (V), alkaline batteries are powered by the reaction between manganese dioxide and zinc metal. Some varieties are rechargeable. Due to their availability and cost, alkalines are a popular battery choice.

Lead-acid batteries use a sulfuric acid electrolyte. These bulkier batteries are often used in cars, golf carts, electric bikes and so forth. A 12 V car battery has six lead-acid batteries inside, each producing 2 V. While they work well in colder temperatures, they have a moderate lifespan and are subject to corrosion.

Other battery options include nickel cadmium, nickel-metal hydride, silver oxide, zinc air and zinc carbon, among others.

To understand the different types of batteries and power usage, it is important to know how they are measured. The relevant metrics are current (ampere or amps), voltage (volts) and power (watts), algebraically represented as:

amps = watts / volts

volts = watts / amps

watts = volts * amps

Think of amps as load, which is measured in terms of electrical resistance (ohms or Ω). To think of load another way, imagine you drive an electric motorcycle uphill. It will run down the battery faster than if you drive it on flat ground. To say that it "runs down" means its voltage falls not to zero, but to a level that it can no longer provide enough volts to power the device. The measurement of how much a battery has stored is called charge, measured in mAh.

IoT batteries of the future and alternatives

Researchers and companies today are testing new types of batteries and battery alternatives, as well as tweaking how IoT devices consume power.

For example, Toyota is researching a solid-state sulfide superionic conductor battery that can recharge in three minutes, while researchers in South Korea are working on stainless steel batteries that could power a cellphone for a week.

Researchers are also experimenting with other metals and chemicals for battery electrolytes, including aluminum, copper foam substrate, lithium sulfur and sodium ion. Another company has replaced lithium ion with graphite. This graphene polymer battery, which charges and discharges nearly 33 times faster than a lithium battery, offers a specific energy of 1,000 Wh/kg, whereas lithium-ion batteries offer 100 to 250 Wh/kg. A graphene polymer battery can reportedly power an electric vehicle for nearly 500 miles.

Other new battery technologies include thin-film solid-state batteries, which are flexible for use in consumer IoT devices and wearables, such as smartwatches, smart glasses, headsets, smart apparel and more.

Traditional chemical energy approaches to storing energy are also being updated. A capacitor, named for its capacity to hold an electric charge, stores static electricity. While an old concept, the supercapacitor is relatively new. Supercapacitors can be charged rapidly but have not gained much traction due to their weight and cost -- for example, the Maxwell D 2.7 V costs around $20 and weighs 60 grams. Supercapacitors are also hindered by an inability to hold a long charge, losing up to 25% of their charge per day.

Is an IoT battery even necessary? Energy-harvesting technologies are emerging as an alternative IoT power source. Researchers have long known power can be generated from light, motion, temperature differentials and motion. Some companies, such as PsiKick and EnOcean, develop batteryless IoT technology powered by indoor and outdoor solar, radio waves, thermal and vibration. This power, combined with ultralow-power IoT device design, offers an alternative to batteries.

However, the sole use of energy harvesting to power IoT is a hot topic for debate, with opponents criticizing the reliability and availability of such power.

To ease these concerns, companies are combining the power of energy harvesting with batteries. Jennova, for example, builds a power management circuit that works with any energy-harvesting transducer, offering a battery backup that enables the device to maintain more than 70% battery capacity. Atmosic Technologies is another company that uses energy harvesting to supplement what it calls a "forever" battery.

Standards and companies are doing their part to lower IoT system power consumption and, therefore, the stress placed on batteries. Using low-power communications protocols, such as Zigbee, Z-Wave or BLE, along with low-power networks, such as LoRa (Long Range) and narrowband IoT, helps reduce the amount of energy required to transmit data. Companies are also building sensors and devices that consume less power. Silicon Labs, for example, offers a portfolio of devices that cuts Wi-Fi power consumption in half for battery-powered IoT devices.

Other energy-harvesting technologies harness the power of electromagnetic radiation. A Mouser power harvester, for example, can produce 5 V of output from -11 decibel-milliwatts of radio power.

In 2015, University of Washington researchers confirmed the ability to harvest energy over Wi-Fi using electromagnetic electricity and proposed a Power Over Wi-Fi standard. They demonstrated that, using a prototype smart home router sending constant traffic and, therefore, creating a steady stream of power, Wi-Fi could be used to charge nickel and lithium batteries up to 28 feet away, which were then used to power a temperature sensor and camera.

More recently, MIT researchers developed a radiofrequency harvester, a rectenna that covers most unlicensed industrial, scientific and radio bands, including Wi-Fi. Using molybdenum disulfide and a flexible Wi-Fi antenna, the rectenna provides wireless energy harvesting of electronic radiation in the Wi-Fi band.

Nanotechnology is also making inroads in the battery space. Researchers at the University of California, Irvine, invented a nanowire-based electrode that encases a gold nanowire in a manganese dioxide shell, which is covered by a Plexiglas-like gel electrolyte. In a test, the electrode was recharged 200,000 times over three months without any loss of capacity or power or any wires breaking.

Many of these concepts are still in the research phase, so it may be a while before we see them in the IoT space. However, researchers are taking steps to not only revolutionize IoT batteries, but also potentially replace them.

Additional reporting by Walker Rowe.